World Engineering Day: Sustainability and opportunity for a better world

Today is the UNESCO World Engineering Day, which recognises the central role of engineers for sustainable development. Through AFCP, engineers across the UK are applying their creativity, teamwork, problem solving and passion to achieve a healthier planet and create a better world.

World Engineering Day, first designated by UNESCO in 2019, is a global celebration of engineers and engineering for a more sustainable, equitable future for all. This year’s World Engineering Day theme is Engineering for a Healthy Planet, marking the launch of the second UNESCO Engineering Report on sustainable development.

Engineers truly underpin what sustainability means in the modern world. UNESCO’s new report highlights the role of engineering for the 17 United Nations Sustainable Development Goals (SDGs). From combatting climate change to supporting new economic developments, driving technological innovation to making these technologies accessible and affordable, engineers provide essential infrastructure for a clean energy future. Through World Engineering Day, UNESCO also advocates for the creation of inclusive opportunities so that people of all backgrounds can help resolve these technical challenges.

Aligned to these aims, engineering teams from the Advanced Fuel Cycle Programme (AFCP) are delivering impact to benefit people and the planet. AFCP’s engineering teams from the National Nuclear Laboratory (NNL), academia and industry are driving the sustainable fuel cycle technologies of tomorrow. In particular, these teams are elevating the UK’s clean energy infrastructure through the development of AFCP’s ten new capabilities, including the Flexible Mini Fuel Line (FMFL) and PuMA-2, both at NNL. The programme is also investing in unique development and engagement opportunities for engineers across career stages.

How is engineering fuelling Net Zero for a healthier planet? Seven AFCP engineers – spanning our technical projects and partnering organisations – share their stories below.

Can you describe what you do, more generally and as part of AFCP?

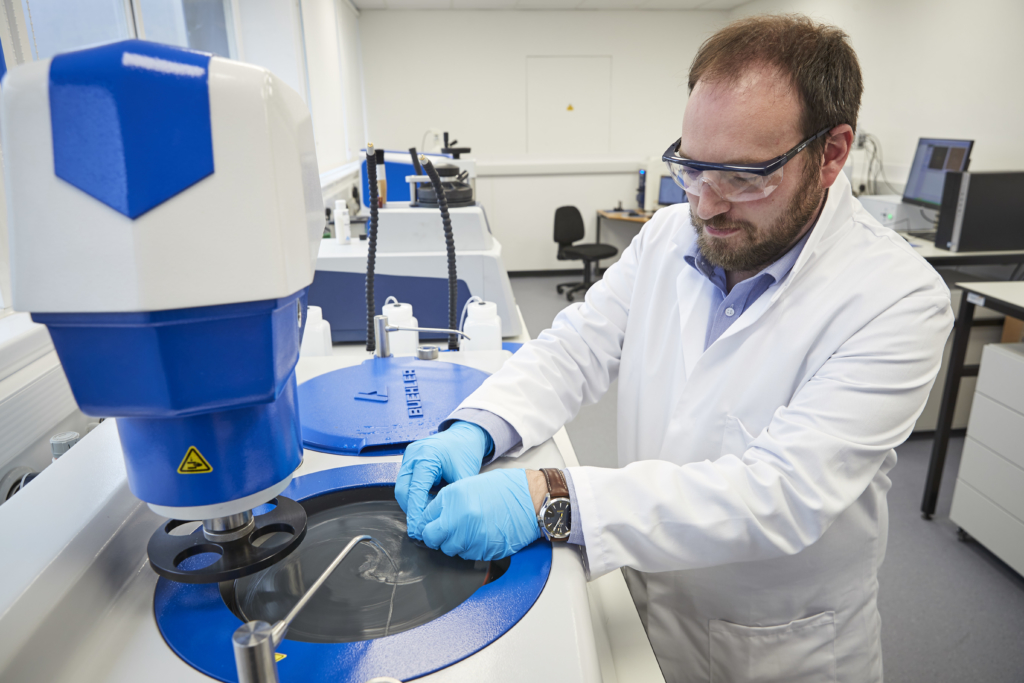

Sam Lyons: In my role as a Process Engineer within NNL’s Engineering Design team, my work entails calculations, report writing and safety assessments. I am responsible for the delivery of design work to support UK Government programmes and ensure continued operation of world-class facilities. Within AFCP, I support both our Fast Reactor Fuels and Advanced Technology Fuels (ATF) projects. I have worked on the development of the FMFL for research and development purposes and more recently started work on the scale-up of ATF manufacture.

Kate Wallace: I’m a solvent extraction modeller working in the Advanced Recycle and Sustainability theme of AFCP. Basically, I predict how to best separate out chemicals in the reprocessing plant. As a computer modeller, I work closely with experimentalists; their data helps me to build better models, and my models help them to design more targeted experiments. As an early career researcher, AFCP is an exciting opportunity to get involved in some juicy research and development!

Simon Middleburgh: My main research areas are developing new, safe, high-performance economical nuclear fuels as part of AFCP and developing new nuclear materials for advanced nuclear systems, such as for space and fusion reactors. At Bangor University, my research focuses on understanding material behaviour using experimental methods and through computer modelling. I have a passion for understanding materials from a mechanistic (nuts and bolts) perspective and believe nuclear engineering has a significant role in combatting the climate emergency.

Leah Etheridge: I am a trainee Radiological & Chemotoxic Safety Assessor based in the Safety Engineering & Assessment (SEA) team at NNL, which means I support the development of safety assessments with the ultimate aim of demonstrating that risk has been reduced to As Low As Reasonably Practicable (ALARP). Within AFCP, I support the Aqueous Recycle project, particularly during hazard identification (HAZOP) and the development of Hazard Management Strategies (HMS) for radiological and chemical hazards.

Melissa Loyley: I’m a Principal Mechanical Engineer at NNL and am generally responsible for the mechanical design of equipment on various projects. For AFCP specifically, I am also the Lead Engineer on the FMFL within the Fast Reactor Fuels project, meaning that I am responsible for the integration of all design aspects of the project, and am the responsible person for all stakeholder reviews.

Harry Rigby: My day-to-day job involves providing process design solutions and progressing designs from concept through to installation and commissioning. Within AFCP, I have been developing the design of an end-to-end test bed for the optimisation of advanced reprocessing flowsheets known as the PuMA-2 capability, which is part of the Aqueous Recycle project. PuMA-2 will also support production of americium to be used as fuel for European Space Agency (ESA) space batteries.

Bruce Hanson: At the University of Leeds, I am the Leadership Chair in Nuclear Process Engineering and Director for Student Education in the School of Chemical and Process Engineering. Here, I oversee a team of PhDs and postdoctoral researcher associates, many of whom support AFCP’s various Advanced Recycling and Sustainability projects. I’m also the Principal Investigator on the EPSRC ATLANTIC consortium, a UK academic group that works closely with AFCP. Having previously worked at NNL, I am now a Visiting Senior Fellow as well.

What did your career path look like prior to joining the programme?

Sam: I attended Newcastle University for five years with a year out in pharmaceutical industry, achieving a first-class master’s degree in Chemical Engineering with Sustainable Engineering. The masters provided me with an insight into what sustainable industry and energy must look like in the future, and the action we need to take as a society now to achieve this. This inspired me to apply to work for NNL.

Kate: I’m actually a physicist by training, but as they often tease, engineering is just applied physics! I joined NNL right after graduating in 2017 and after a few placements settled in the Separation Science and Special Nuclear Materials team (SSSNM). For my current role, there was a lot I had to learn (new chemistry, new software), but it is interesting, challenging work – the kind I love most.

Simon: In 2008 I was offered a PhD position modelling nuclear materials under Prof Robin Grimes FRS. I got the bug for nuclear engineering straight away and saw that the combination of extreme materials and environments could occupy my mind for a career or so. Subsequently I did a world tour working at ANSTO (Australia), before joining Westinghouse (Sweden/USA) developing the next generation of nuclear fuels and reactors – work I continue here in Wales.

Leah: I studied Chemical Engineering (BEng) at the University of Huddersfield and undertook a placement year with a global manufacturing firm within their Lean Manufacturing department. I joined NNL’s graduate scheme in 2018, having had no prior nuclear experience, first based in one of their Cumbria facilities as a non-active rig operator before joining the SEA team in 2019. I am also one of NNL’s Equality, Diversity & Inclusion Leads, focusing on encouraging career development and removing barriers to progression.

Melissa: I studied Mechanical Engineering at university and my first postgraduate role was in the opto-mechanical industry. I moved to nuclear in 2007, initially at Atkins, and worked on various projects, several of which were site-based. Since moving to NNL in 2017, I have been responsible for defence and civil nuclear projects, specifically looking at glovebox and self-contained projects.

Harry: Nuclear was the obvious choice given it’s a great opportunity to sit at the forefront of an industry which is on the cusp of moving into its most exciting and prosperous period in existence. Since joining NNL six years ago, I have progressed from Graduate to Process Engineer to my current position of Senior Process Engineer and have notably worked on projects in advanced fuels (ATF/TRISO) and advanced reprocessing whilst dabbling with some rig operations work.

Bruce: Before joining Leeds six years ago, I spent over 25 years in the nuclear and chemical industries across many different functions. After graduating with a degree in chemical engineering from UMIST, I worked at a range of organisations including British Nuclear Fuels Ltd, Bush Boake Allen Ltd and NNL. My experience has included plant modelling and simulation, supporting the design for the Thermal Oxide Reprocessing Plant (THORP) and leading R&D programmes for spent fuel and nuclear materials at NNL.

What challenges are you trying to resolve through your AFCP project? Why is engineering essential to overcome these challenges?

Sam: The FMFL capability I have worked on the design of will enable research and development into fuel pellets of various compositions and as such is of vital importance to the future of our industry. The collaboration across all engineering disciplines has been pivotal in the development of the capability to ensure the desired operations can be achieved. The manufacture of ATF will be important in the operation of future reactors.

Kate: By developing reprocessing technology, we expand our waste management options. Reprocessing could have many advantages: less waste, easier to treat and manage waste, reuse of fissile isotopes in new fuels, and even useful secondary by-products – americium for space batteries and source materials for medical isotope generation. Anything that reduces waste and increases useful products helps to make the whole nuclear fuel cycle more environmentally friendly, sustainable, and economical.

Simon: We are building a new UK facility to test existing and novel fuels in new reactor environments, such as for lead fast reactors, whilst developing novel fuels that may be powering these reactors. The fuels we are developing combine the safety aspects of current systems with step-changes in performance by incorporating new materials – a composite nuclear fuel. The fuel must perform in one of the most extreme environments, which is a wonderful engineering challenge for my team.

Leah: The project that I support aims to demonstrate advanced reprocessing techniques with access to a greater inventory, more functionality and enhanced analytical capability to minimise the amount of testing required in a High Active (HA) cell. A multidisciplinary and collaborative approach amongst the engineering disciplines is pivotal to the success of these challenges as it provides diversity of thought in order to solve complex problems and provide innovative solutions.

Melissa: Whilst I’m aware of the general need for engineering on AFCP’s Fast Reactor Fuels project, my day-to-day challenges are more about ensuring that the detailed design for the FMFL runs smoothly. This means that all the engineering disciplines need to work together for a common goal. I also need to consider scheduling of resources, availability of testing facilities and ensuring that any supplier provided equipment arrives where it should be at the time it should do.

Harry: The PuMA-2 capability is being designed to incorporate online process monitoring and control (which requires intricate, novel engineering), optimisation of advanced reprocessing flowsheets (flexible, reconfigurable design of equipment enables a range of flowsheets to be operated) and elevated throughput (upscaled equipment, high volumes of feeds, products and wastes to be processed). Additionally, use of PuMA-2 to produce americium for ESA space batteries needs to meet a yearly product yield, requiring a process that is slick and reliably engineered to minimise operating downtime.

Bruce: As we develop new technologies, we move up the Technology Readiness Levels (TRLs). To achieve TRL 9 – meaning that the technology has matured to where it’s operationally used at an active facility – we not only need to solve the scientific challenges, but we also need to have an engineering solution. On AFCP, I am trying to create those engineering solutions that allow us to implement the new technologies being developed across the programme.

What sparked your initial interest in engineering, and how are you applying this today as part of AFCP?

Sam: It was my A-Levels maths teacher who suggested I study chemical engineering due to my passion for the sciences, and this is something I have not regretted. The opportunities available in engineering are broad, requiring a huge spectrum of skills such as innovation, collaboration and the application of knowledge to new challenges every day. These challenges will often be tasks which will benefit wider society and therefore come as motivation in my work.

Kate: My degree gave me the numerical and computational skills that serve me well in my current role, and mostly importantly, an inquisitive mindset, able to debug, problem solve and follow the logic of the systems we model. When I was applying for my first job, I thought, what are the key challenges of my time, and how can I help? The energy mix and low-carbon electricity stood out, and NNL got my attention with one line: we operate in the space between university and industry. This role – taking new techniques and research and finding ways to practically apply them in the real world to solve real-world problems – was exactly what I had been looking for.

Simon: It is a cliché: from an early age, I was always taking things apart and trying to understand how they worked. Although I didn’t take them apart, my first passion was to be a vet and fix animals, but my next-door neighbour worked for Magnox and showed me his work crashing trains to prove wasteforms were safe (which was eye-popping) and my PhD supervisor crystallised my interest in nuclear through solving big problems that will have an international impact.

Leah: Engineering is a vastly broad field which offers a variety of diverse career opportunities. The attributes of an engineer – such as critical thinking, creativity, teamwork and communication – are often, if not always, transferrable across projects and can be applied in multiple scenarios. This has provided me with a platform to work on a variety of exciting projects that benefit society, both now and for generations to come.

Melissa: I’ve always been interested in engineering. Helping my dad maintain cars at the age of five really sparked my interest. I like knowing how things work and how improvements can be made to make everyone’s lives better and easier. Part of being an engineer is looking for the best applicable solution to a problem and having quite an analytical brain really helps to sort through all the data to ensure that the best solution is put in place.

Harry: Like most, whilst at University I was still unsure of exactly what I wanted to do. I’d been learning Chemical Engineering theory, but it wasn’t until my third-year design project that I had the chance to really apply it and I enjoyed it. Working as a team, using combined knowledge to collaboratively solve real-world engineering problems – that’s what engineers do, and it translates perfectly across to my current design role now as part of AFCP.

Bruce: I spent 25 years or more designing and working on plants that built on earlier developments. The challenge of turning a great idea in the lab into something that can be built and operated is why I am an engineer and the challenge of something that is new and has not been done before is what draws me to AFCP.

Are there any misconceptions about being an engineer in nuclear that you’ve encountered? How can we overcome these misconceptions to help encourage more people to enter careers like yours?

Sam: I believe the nuclear industry is regularly misconceived by those outside of it. However, being an engineer within the sector, you appreciate the amount of work that goes into ensuring safety, thus enabling us to complete the vital work which will help us reach Net Zero. This work and the subsequent opportunities should be advertised to wider society to show the excitement such a career can entail.

Kate: I think one thing people probably don’t realise is the range of roles that make up the nuclear industry. Contrary to popular opinion, most of them don’t have much to do with radiation. Infrastructure, fluid dynamics, robotics… there’s a wide variety of ways to contribute. Don’t let ‘not knowing much about nuclear’ hold you back from a career in the industry – we’re learning from neighbouring industries all the time.

Simon: Many people think that a nuclear engineer must be (a) ridiculously clever and (b) a serious individual. There is also the misconception that the industry is secretive, which should be shed, especially for commercial systems. Diversity in the workplace breeds diverse and innovative ideas. We can’t all be excellent mathematicians and most people can bring something to the engineering table. As engineering is a team sport, we must also embrace the lighter side of working in a team.

Leah: The nuclear industry is often misconceived as being old fashioned. However, whilst years of experience means that things are often well understood, our industry is extremely innovative and thrives on continuous improvement. By sharing our experiences and providing diverse role models which aim to inspire all parts of society, we can attract a diverse and talented workforce.

Melissa: I think The Simpsons has a lot to answer for, particularly for my generation. Everyone seems to think that uranium glows green and that all nuclear workers have a weird, glow-in-the-dark aura. I’ve been privileged to get involved in both national and international conferences as part of my volunteer work with the Nuclear Institute to try and challenge these misconceptions. Not all nuclear engineers wear full hazmat suits all the time – some of us work in an office, and that doesn’t change the importance of the work we do.

Harry: I was once told that I would be ‘bored’ in nuclear. Sure, engineering programmes are often longer with work being much more stringently assessed and regulated when compared to more conventional industries. However, the constant exposure to creativity, unrivalled subject matter expertise and pioneering technologies along the way makes for a far from ‘boring’ experience. The key is to be open-minded and be prepared to step out of your comfort zone every single day.

Bruce: There’s sometimes a misconception that nuclear engineers are not interested in anything new. What is really the point is that we need to feel confident it will work before we put faith in it. If you can prove that a new piece of technology works really well, then everyone in the industry will want to use it.

What advice would you give to engineers just starting their careers within nuclear, clean energy or advanced fuel cycles?

Sam: You are the future! We cannot continue to sustain our world in the coming decades on current sources of energy, and the use of innovative nuclear and clean energy sources is going to be essential. The opportunities and challenges will be exciting and will mean that your development can only ever continue. The contribution you make to a more sustainable world is going to be key.

Kate: Be patient! You may want to feel like you’re making a difference immediately but reaching Net Zero is a long-term goal. Sometimes, the future we’re working towards can feel a long way away. In times like that, I remember: You are not obligated to complete the work, but neither are you free to abandon it [Pirkei Avot 2:21]. Your individual contribution may feel small, but if we all contribute a little, we’ll get there.

Simon: Being an engineer is a team game and one should be careful to grow your work network from the earliest opportunity. Nuclear is no different, and if anything, the networks are even tighter. So be honest, be open, ask for help with projects and communicate clearly – others will be happy to be involved! With nuclear it is important to know your facts as it remains a contentious subject, so keep reading and questioning the status quo.

Leah: There’s always more to learn. And whilst this may be daunting at first, it will prove to be exciting and provide you with opportunities you never knew existed! A secondary school teacher once told me, ‘your attitude will always determine your altitude in life’ and only now do I truly appreciate its meaning. Our greatest growth comes from overcoming our greatest challenges.

Melissa: I’d give the same advice as I do to the school-age people that I mentor – speak to as many people as possible in your preferred career to get as much advice and as wide a range of advice as possible. My career didn’t start in nuclear and was more of a happy accident. However, it is work that I enjoy and it is challenging. Luckily, I enjoy a good challenge. Be prepared to get involved in things outside of your comfort zone and don’t be afraid of asking for help when needed – no one knows everything.

Harry: Invest your interest in the overall goal from the outset and seek as many opportunities as possible to broaden your knowledge, skill set and network. In doing this, you’ll obtain a crucial level of knowledge of how each part of the industry operates and can collaborate with the next. Understanding this is one of the more powerful tools an engineer can yield.

Bruce: You have to keep an open mind and be prepared to change your view, but always follow what you believe to be the best way forward. The world is very different place to when I started as an engineer and nuclear energy has fallen in and out of favour, but I have always believed it was the right way to generate power and we now know that it is a key part of our zero carbon plan.

In describing the key message of World Engineering Day, UNESCO comments: If you want to change the world for the better, become an engineer. In your own words, how is your work contributing to a better world?

Sam: Being an engineer in the sustainable energy industry, the work I partake in will make a difference to society. Within the engineering team at NNL, our collective solving of problems and overcoming of challenges provides the capabilities for both research and manufacture, ultimately making a significant contribution to the future of cleaner energy.

Kate: Nuclear power will be a key element of a Net Zero energy mix. But to get plants built in time we have some key challenges, such as hesitancy due to fear of nuclear waste. My work can help reduce the burden of past, present and future nuclear waste. Cost reduction of reprocessing plants is also a key focus, and as our models improve, the efficiency of plant designs improves, helping to reduce the build and operation cost.

Simon: I want to create – and work with – teams that develop key technologies that will help me to pass a better, more sustainable world on to my children and future generations. Nuclear has a special role to play in not only powering our homes and industry, but also improving our health, decarbonising and accelerating our industries, advancing other sectors and even propelling us to new worlds.

Leah: Engineers provide solutions to challenges with the aim of improving the lives of people across society – this may range from providing clean energy in order to heat homes or power cars to effectively recycling materials which may otherwise be ‘waste’. Safety engineers ensure that we do this safely by managing risk in line with best practice guidance and regulatory requirements.

Melissa: As part of AFCP overall, the FMFL capability is one of the initial steps in ensuring fuel quality and diversity. The engineering work behind the science ensures that we can provide a safe and reliable platform to enable the science to take place.

Harry: I believe the nuclear industry is in a truly fortunate position in that hasn’t harnessed its full potential yet and the time for us to do so is imminent. As engineers, we have this unique opportunity to take the novel ideas and concepts developed as part of programmes such as AFCP and make them real. In doing so, we can offer a major contribution toward national and international initiatives, like the UK’s goal of Net Zero by 2050, and progress them even further.

Bruce: It will take the work of many, many people to solve our problems and make a better world. As an engineer, you’re locked into the idea of teamwork and working with people across a range of disciplines. Embrace this skill and use it to your advantage to find those engineering solutions that are going to make a difference.

Thank you to all the brilliant engineers across AFCP who are fuelling Net Zero for a healthier planet and clean energy future!

AFCP is part of the Department for Business, Energy and Industrial Strategy (BEIS) £505m Energy Innovation Programme.